There are many benefits of goods-to-person robots that you’ll witness over time—the major ROI you’ll get and the time you’ll be able to devote to other value-added processes while warehouse automation technologies do the job are just a few of them.

However, there are also some significant benefits of goods-to-person robots that you’ll experience instantly, almost minutes after you click start. Wonder what they are? Keep reading. 👇

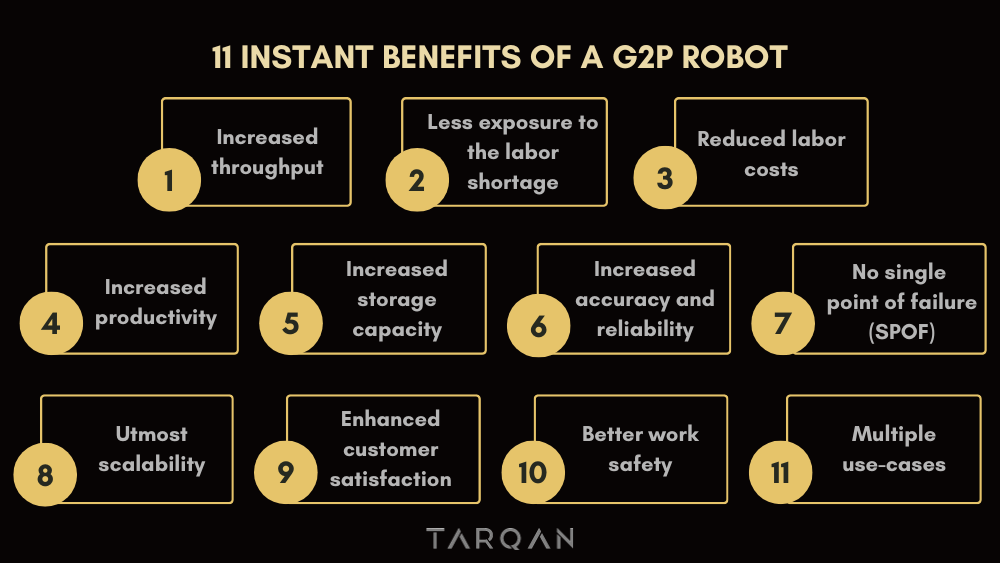

The 11 Advantages of Deploying Goods-To-Person Robots

From better work safety to optimized customer satisfaction, there are many ways your fulfillment operations can take advantage of goods-to-person picking systems.

1. Increased throughput

Goods-to-person robots can increase throughput and efficiency in a number of ways. The most prominent way lies in how the goods-to-person system works—they eliminate the need for workers to spend time finding, picking, and walking goods around the warehouse.

In addition, most goods-to-person systems are built with smart navigation systems which determine the best route to bring the products to the picking station, which provides you with quick yet efficient picking processes the minute you start to use them.

2. Less exposure to the labor shortage

In today’s economy, the labor shortage is a serious issue. So much so that the latest data indicate over 10 million job openings in the U.S., with only approximately 6 million unemployed workers.

Luckily, G2P robots are designed to take on the highly repetitive and physically demanding tasks of order picking, which warehouse employees would otherwise perform. Thus, by automating these tasks, warehouses can reduce their reliance on human labor, making them more resilient to the effects of the labor shortage.

3. Reduced labor costs

One of the most prominent benefits of goods-to-person robots is that they provide warehouses with cost-efficiency. How?

G2P robots are designed to move around a fulfillment operation, find the rack or shelf a product is, and bring that to the picking station. Thus, they eliminate the need, and cost, that goes into recruiting, or employing, warehouse workers for these picking processes.

The best part is those who have automated order fulfillment processes can now employ their employees in other processes and compensate for the lack of labor they’re most likely experiencing amidst an era of labor shortage.

4. Increased productivity

Goods-to-person picking systems can improve your picking productivity by 300%. How?

While a person collects 120-150 products per hour, a G2P robot like TARQAN collects 400-500 products per hour.

So, not only do you do more in less time, but you also ensure faster order fulfillment cycles, which will ultimately improve your business in many ways.

5. Increased storage capacity

G2P robots are truly a game-changer when it comes to warehouse efficiency—increasing storage capacity is only one of them.

Conventional fulfillment operations are reliant on humans to travel within the warehouse. This system requires wide walking areas to allow humans to stroll through the warehouse, carrying around the products.

That’s where the benefits of goods-to-person robots kick in again!

Since G2P robots bring the goods directly to the picker station, it eliminates the extra area needed by humans and converts that space into storage units. Then, all left to do is for the fulfillment robots to get under the racks and carry them throughout the warehouse.

The smaller a G2P robot gets, the more storage space it provides. That’s why TARQAN, the thinnest G2P within its class, is able to offer 10% more storage space than its competitors.

6. Increased accuracy and reliability

There are many SKUs in every fulfillment warehouse with very little space to dedicate specific bins, let alone racks, to them. Thus, picking processes can be very prone to error as a human walks down the aisles, sorting their way through numerous SKUs to find the correct one.

Luckily one of the instantly recognized benefits of goods-to-person robots is that they are the answers to one of the most commonly asked questions within a fulfillment operation—how to improve order picking accuracy?

The second you receive an order, these robots know in which aisle, rack, and even bin the products are. So, they bring that specific rack to the picking station, increasing order picking accuracy by 99.99% and leading to more reliable processes.

7. No single point of failure (SPOF)

Most G2P robots are built to mitigate the risks of a single point of failure. Thus, when one of the robots within the fleet (malfunctions, is no longer able to operate, or is simply on low battery), the remaining fleet can quickly organize to ensure continuous processes.

This is an important risk management technique for G2P robots, minimizing downtime and ensuring that your operations run smoothly.

8. Utmost scalability

There are many times within a year, such as the peak seasons and your brand-specific discount days, that you may experience a spike in your order volume. When that’s the case, you need more resources to make sure you keep up with the increased demand.

G2P robots are perfect for such situations as you can upsize and downsize your operations as you wish by eliminating the lengthy and costly process you’d normally have to go through to employ warehouse workers.

9. Enhanced customer satisfaction

Cost efficiency, boosted productivity, and increased throughput may be the first benefits of a goods-to-person robot that comes to mind. However, these robots also have a significant impact on enhancing customer satisfaction. How?

G2P robots are designed to quickly and accurately pick the items within an order. This automatically helps speed up the packing and shipping process, which in turn helps to deliver orders, again, more quickly and accurately.

Considering 86% of your customers may leave your brand after only experiencing two poor customer experiences, this is just another sign for you to deploy a goods-to-person technology.

Don’t know where to start? Contact one of our automation experts!

10. Better work safety

G2P robots are also known to decrease work injuries to a very large extent in 2 very important ways:

- G2P robots help reduce repetitive motion injuries by performing tasks such as lifting and carrying products, which normally are executed by humans.

- Most fulfillment robots operate in humanless environments, mitigating the risk of serious collisions, which warehouses are usually prone to.

11. Multiple use-cases

Last but not least, one of the most overlooked benefits of goods-to-person robots is that they offer more than their name suggests!

Alongside their incredible performance in picking processes where they bring the goods to the person, which is their main use case within most warehouse operations, G2P robots can be utilized in various other inbound operations, such as stock replenishment and put-away processes.

What are the other use cases for a fulfillment robot? Contact one of our experts to learn more!

All in all…

Deploying goods-to-person automation is the first and most important step you can take to improve your overall fulfillment operation.

The best part is you’ll start realizing the various benefits of goods-to-person robots right away, whether you’re an eCommerce business with in-house processes or a 3PL or 4PL that’s looking to provide its clients with tech-enabled fulfillment services.

Contact us today to start your automation journey with TARQAN!